Intake Ports |

Back to the Head page Back to LowBugget.com How to place your order For more info call the shop and ask for A.J.Sims 714-639-4284 |

Some shops will give you the top flow numbers of their heads to help boost sales

or make it sound like they will make more power than the other heads. I do not

live and die by the flow bench. Although my heads tend to do very well on a flow

bench they do better on a dyno. A flow bench will show what air will do

when forced through an orifice, or port. But it will not show what air with fuel

will do. If a flow bench flowed only fuel would it change how you think about

ports and their designs? Because of this I do not sit on a flow bench all day

trying to find that last cfm number. I This might sound funny but I have a different way of doing things. Like how I cut the spring boss larger to support the guide on the back side were the springs sit. See Guide Boss for info. |

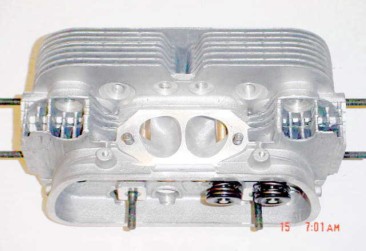

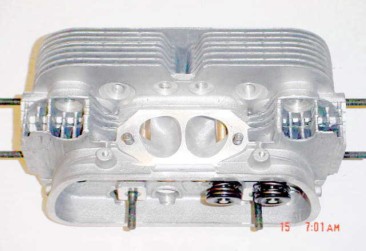

The Intake Port. The most important part of port and polished heads. The intake ports must flow an adequate amount of air and fuel evenly to each chamber. This must take place with the least amount of restrictions and obstructions. At the same time it must have sufficient air speed to keep the fuel and air atomized. So bigger is not always better. A very large port might supply air and fuel to a 9,000 rpm motor but it needs that much draw on the port to keep the fuel and air atomized. If there is not enough draw on the port the fuel and air will separate. At the same time you do not want a small/ restricted port. Some info about CNC Heads. Some people think that CNC heads are good for their matched ports. Now when I say matched ports I do not mean by their looks. I mean thier flow or CFM. They are wrong. The down side to a machine porting your heads is it does not know about the irregularities from the molds and mostly the machinest. It was up to the machinest to properly load the part into the machine. Take a look. Notice in this pic how much meat/aluminum is on the left side outer edge of the intake port compared to the right side. Its not that the holes are a different size, Its just the machine did not know that the head was sitting off to the left side. Thats why when I put my templet on and scribed these heads you will notice more meat on the left of the port than on the right. Now i know to remove more meat from the left side of each port than the right. |

Notice in this pic how the head tin screw is sitting lower on the block. Its not that the hole was drilled off but the head was loaded high. |

The last one you can see how the head nut surface area/washer seating surface is

off to the 10 clock postion. i |